winds of change:

Chemship in are committed to reduce our CO2 footprint

“it is not only saving cost, more importantly it is about reducing the CO2 emissions”

Niels Grotz

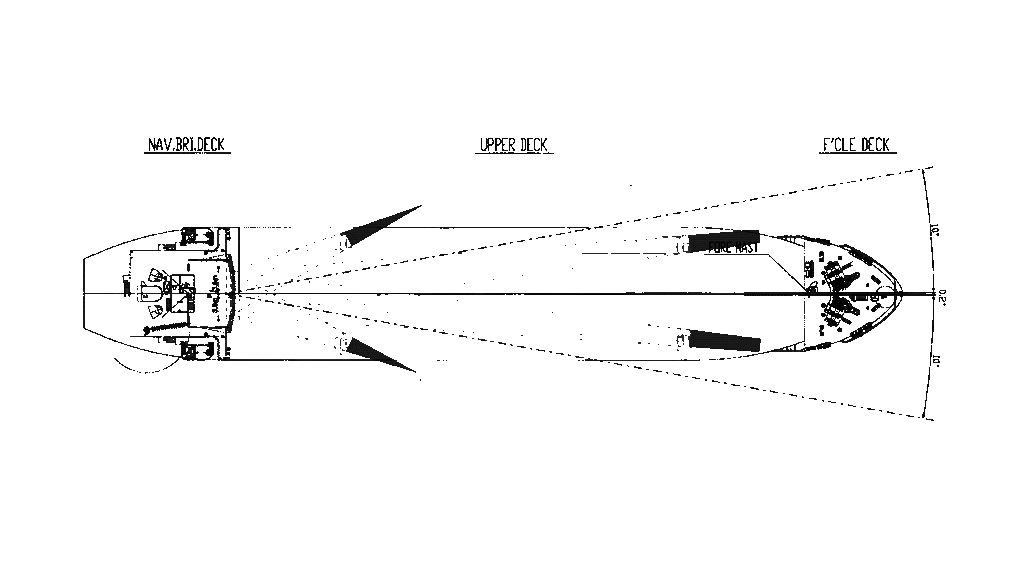

The shipping industry in general and we at Chemship in particular, are committed to reduce our CO2 footprint, not only by the means of legislation, but also with technical improvements on board of our vessels. In the big “ocean” of global shipping, Chemship has been making waves by installing Ventofoils on board of MT Chemical Challenger, making this vessel the first chemical tanker in the world equipped with “sails”. This wind assisted propulsion (WASP) has been developed by a Dutch startup Econowind and is the most visible measure on board of the ship to reduce the CO2 emissions. The project which was initiated by our operations Director Michiel Marelis, started in September 2021, when he met with the technical professor of Econowind. Michiel had to overcome various challenges and the whole project contained design, testing, re-shaping, class approval, testing and last but not least installation on board of MT Chemical Challenger. A reporter of Tradewinds who was present during the inauguration of the sails asked how much fuel cost could be saved by the Ventofoil, to which CEO Niels Grotz stated, “it is not only saving cost, more importantly it is about reducing the CO2 emissions”.

More than one year on: Reflecting on the Ventofoils

It’s now been more than one year since we successfully installed the Ventofoils. What started as a cautious venture with a small, innovative startup has developed into a confident and valuable collaboration.

Looking back, we expected a few setbacks. And indeed, we had some technical hiccups in the beginning. But over the past year, the Ventofoils have proven their resilience and effectiveness. They’ve endured everything we’ve faced: from stormy Biscay crossings to two transatlantic voyages and they’re still standing strong.

From the very first passage, we saw their potential: a speed gain of 0.8 knots at just 4 Bft. Since then, performance has only improved. Thanks to the responsiveness of the Econowind team and the dedication of our own crew, technical issues became less frequent and are now rare.

Over the last months, we’ve shifted into a new phase optimization. The fuel optimization system is now fully operational, allowing our engines to run at optimal efficiency by intelligently adjusting to wind support in real time. This is already translating into measurable fuel savings and lower emissions.

We’re proud to report that the Chemical Challenger continues to be our top-performing vessel, consistently operating at CII A rating. Despite not yet having the silicon paint upgrade, and despite our demanding trade pattern. Our intensive port operations limit the distances we cover, which makes maintaining high CII ratings challenging. Yet, thanks to innovations like the Ventofoils, we’re achieving impressive results.

In our next e-magazine update, we hope to share a comprehensive analysis of actual CO₂ savings. Data we know is of high interest to many, ourselves included.

Sailing sustainably is no longer an ambition. It’s becoming a reality.

Why using friction-reducing coatings?

Chemship has implemented the use of friction-reducing coatings on its fleet to enhance fuel efficiency and reduce environmental impact. These advanced coatings are applied to the hulls of vessels, minimizing resistance as ships move through water. By lowering friction, Chemship not only improves operational performance but also decreases fuel consumption and CO₂ emissions. This initiative aligns with the company’s commitment to sustainable shipping and continuous innovation in maritime technology.

Efficient Engine Performance with Dex Oil

Chemship utilizes Dex Oil as part of its commitment to maintaining high-performance and reliable vessel operations. Dex Oil is a premium-grade lubricant known for its durability, efficiency, and ability to protect critical engine components under demanding marine conditions. By using Dex Oil, Chemship ensures optimal engine performance, extended maintenance intervals, and reduced wear and tear, contributing to both operational efficiency and environmental responsibility.

Enhanced Propeller Efficiency with Boss Cap at Chemship

Chemship employs the Boss Cap on its vessels to improve propeller efficiency and reduce energy loss during operation. The Boss Cap is designed to streamline water flow around the propeller hub, minimizing turbulence and lowering fuel consumption. This innovative addition supports Chemship’s ongoing efforts to enhance vessel performance, reduce emissions, and promote sustainable maritime practices.

Optimized Fuel Management with FuelOpt and WAP/ALS at Chemship

Chemship uses the FuelOpt system combined with WAP (Weather Adapted Power) and ALS (Adaptive Loading System) to maximize fuel efficiency and operational control. FuelOpt ensures real-time engine optimization by automatically adjusting propulsion power, while WAP and ALS adapt engine output to weather conditions and cargo load. This integrated solution reduces fuel consumption, minimizes emissions, and supports Chemship’s commitment to sustainable and cost-effective shipping.